Case Studies

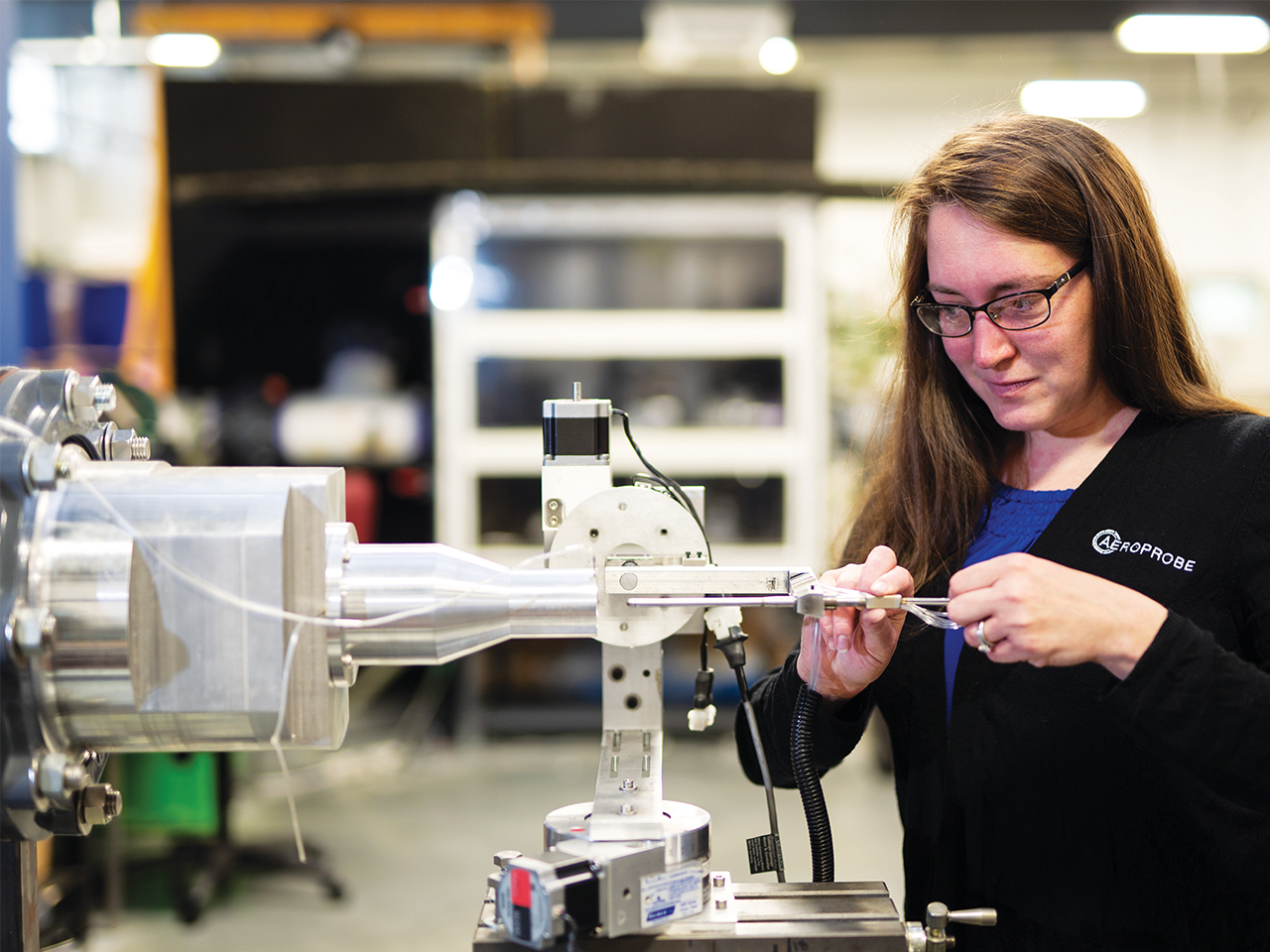

Aeroprobe Sets Companies Up for Speed

Formula 1 race cars, wind turbines, NASA rockets, and unmanned aerial systems (UAS) optimize performance based on how air flows around their surfaces at various speeds, altitudes, and temperatures. Aeroprobe, based in Christiansburg in the New River Valley, manufactures the advanced sensors and measuring devices upon which these cutting-edge systems around the world rely.

“From air flowing through turbine engines, to how it moves around a car’s hubcaps, having the ability to precisely measure air patterns, speeds, pressures, and directions are critical,” Aeroprobe President Nathaniel Varano said. “The level of accuracy of the measurement is directly related to the level of refinement of the design. It is a very specialized science.”

“Our customers are on the cutting edge of their industries,” he added, “whether it’s designing next season’s F1 race car or the next-generation of autonomous aerial vehicles. Our job is to make sure they have the most accurate and reliable air data measurements so they can perform at the highest level.”

Products Enable Unmanned Innovation

While Aeroprobe’s family of air data and flow measurement systems are the established choices in many high-tech industries, the company’s biggest growth opportunity is the global potential for both autonomous and remotely piloted UAS.

“Right now, in the UAS market, our Micro Air Data System is our most popular product,” Varano said. “We make several different models, but they are all small, lightweight, and use little power, which makes them an excellent choice for use on all types of unmanned systems.”

That system is in use with numerous leaders in the unmanned field. While many Aeroprobe customers don’t publicize their projects for privacy and security reasons, these publicly known projects used the Micro Air Data System for various applications:

- Measuring the angle of attack and angle of sideslip during drop tests of the Sierra Nevada Corporation’s Dream Chaser spacecraft

- Providing airflow measurements for Prismatic’s PHASA-35 solar-powered high-altitude, long-endurance UAV for flights up to 50,000 feet and as long as one year

- Providing airspeed, angle of attack and angle of sideslip measurements for Delft University of Technology’s Silverwing entry into Boeing’s GoFly personal flying vehicle competition

Aeroprobe’s customers rely on the company’s compact, integrated air data systems to accurately monitor a craft’s angle of attack, sideslip, air speed, and altitude. That information is sent to the onboard flight control system in real time to improve the vehicle’s stability and performance during all phases of flight. It’s particularly critical during takeoff, landing, and higher-risk maneuvers.

“Because the data is collected in real time, the flight control system can quickly alter the angle of attack, for example, to avoid the loss of lift due to aerodynamic stalls,” Varano said. “Without the information our products provide, aircraft performance would suffer, and some sophisticated unmanned aerial systems may even be unflyable.”

Aeroprobe's Global Goals

Domestically and internationally, Aeroprobe has an established presence with a variety of energy production, transportation, and research companies. But the rapid acceleration of the unmanned aerial systems market has necessitated the refocusing of efforts to increase its global presence.

The company has been able to draw on the experience and expertise available through their long association with VEDP’s international trade program, notably the Virginia Leaders in Export Trade (VALET) program.

Maintaining Excellence in Virginia

Aeroprobe’s reputation in the industry has been built on more than just the accuracy and reliability of its products. The company will recommend competing products if they better fit the customer’s individual needs.

“That kind of honesty can be hard to come by, but it is necessary to build trust,” he added. “In the end, we want our customers to know that Aeroprobe is a valued partner. It’s sometimes a longer road, but a more rewarding one for our team and our customers.”

Competing in a cutting-edge field requires access to top-tier talent. A critical element of Aeroprobe’s ability to attract the talent it needs is its Virginia location, minutes from Virginia Tech’s world-renowned Kevin T. Crofton Department of Aerospace and Ocean Engineering — ranked fifth worldwide by the most recent Center for World University Rankings — as well as Radford University, where the physics department offers a dual degree program with Virginia Tech’s College of Engineering. Students who complete the five-year program graduate with bachelor’s degrees in physics from Radford and engineering from Virginia Tech.

“Being here in Christiansburg gives us a centralized location in the New River Valley corridor,” he says. “We’re fortunate to not only have so many universities and colleges to recruit from, but there are also so many great small and midsized technology companies, which draw an active community of entrepreneurs and technologists.”

Like numerous other companies, Aeroprobe has found fertile ground for scientific innovation in the New River Valley — and strong markets for its products overseas.